rhythm 2.0 Auto Industry Solutions

rhythm 2.0

Auto Industry Solutions

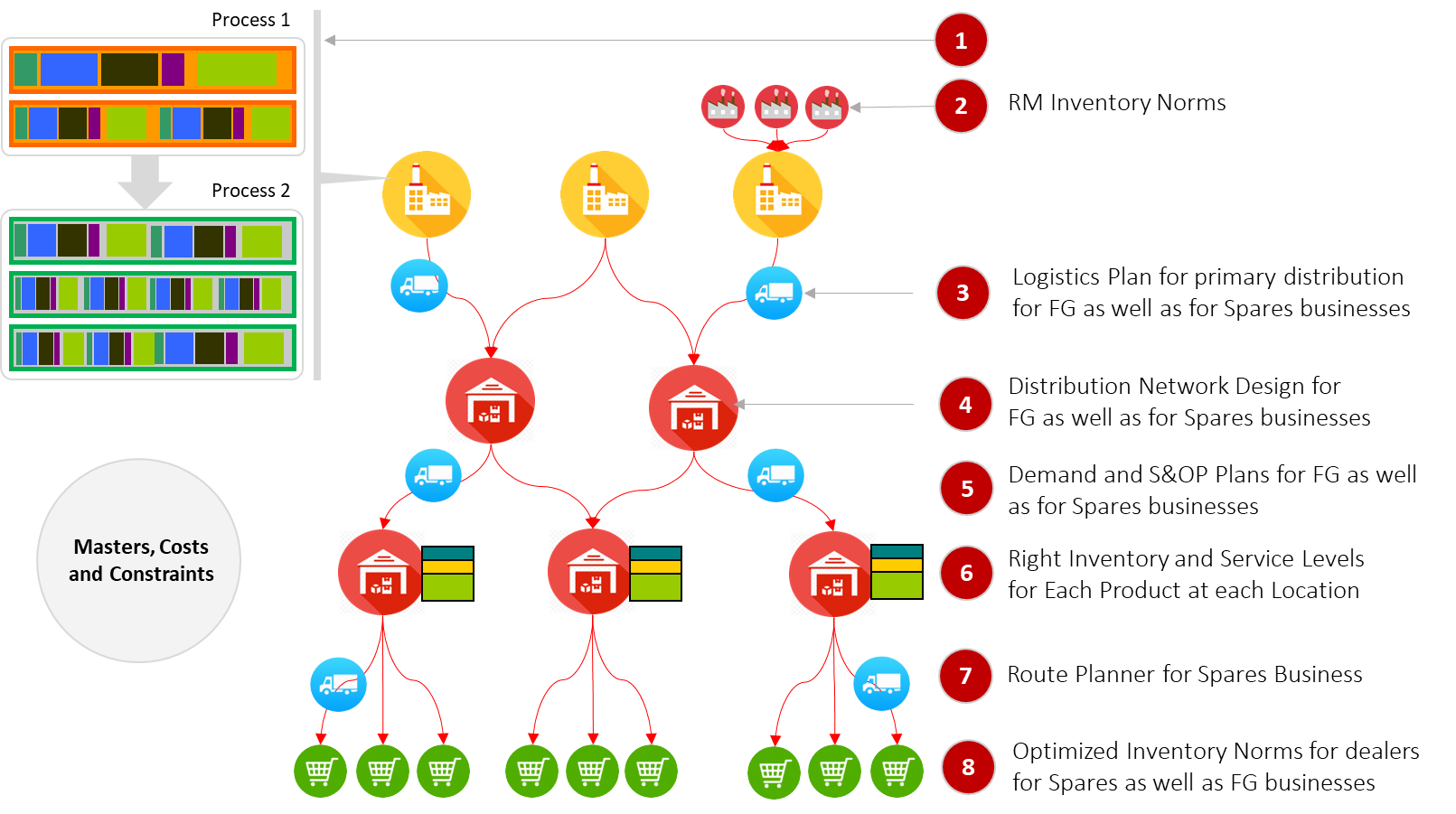

rhythm 2.0 Auto solutions are widely applicable for addressing different aspects of the Auto Business from Factories to Supply Chains to Customers. They work equally well for the main Finished Goods as well as for the Spares business.

Key Modules and Auto Use Cases

- Distribution Network Planner - Optimizes complete Distribution Network to find the right number, location, role and capacities of the warehouses to minimize supply chain costs and maximize Service Levels. Relevant for main Auto as well as for spares businesses.

- Inventory Planner - Finds right relationship between Stock and Service Level based on various parameters and optimizes Inventory. Relevant for main Auto Raw Materia and Finished Goods as well as for spares businesses. Can optimize own as well as dealer working capital and can generate very good results for complex spares business with large number of parts and dealers having very high demand as well as supply variability. Learn How.

- Logistics Planner - Generates distribution plan from Factories to the final delivery points through various levels within Supply Chain. This can ensure high level of compliance with the optimized results delivered through Distribution Network Planner.

- Route Planner - Considers daily or historical orders and optimizes the vehicle loading and delivery routes to large number of Customers. Relevant for spares businesses for the secondary and last mile distribution.

- Demand Planner - Generates unconstrained consensus demand forecast through top down or bottom up approaches and combines with statistical forecast.

- S&OP Planner - Enables evaluation and collaboration for selecting a Sales & Operations Plan that aligns with the financial goals.

- Production Sequencer - Plans production sequencing of the Finished Goods based on Demand and changeover constraints.

- Manufacturing Execution System (MES) - Tracks production and material quality at all stages within Shop-floor and gives full visibility of Order and Material Status.

Deliverables in a Snapshot

Some Case Studies

An iconic Auto Manufacturer optimized Dealer and its own Working Capital for its Spares business by over 25% and improved Service Levels by 10%. The problem entailed over 50,000 parts deployed at over 1000 dealer locations. Understand How.

An Iconic Auto Manufacturer discovered potential of nearly 50 million USD annual saving in its Distribution Cost of its Commercial Vehicles through optimized linkages, warehouse locations, mode of transport and product at plants. Understand How.